Standards and guidelines

GENERAL REQUIREMENTS FOR GLOVES: EN 420

Standards and guidelines are an essential factor in the production of protective gloves. The EN 420 standard specifies the relevant test methods and general requirements to be applied to all protective gloves. These include design principles, glove manufacture, resistance of the glove material to water penetration, harmlessness, comfort and performance, as well as the labeling and information to be provided by the manufacturer.

EN 388:2003 MECHANICAL RISKS

Abrasion resistance (0 – 4)

Cut resistance (0 – 5)

Tear resistance (0 – 4)

Puncture resistance (0 – 4)

EN 388:2016 MECHANICAL RISKS

EN 388:2016 MECHANICAL RISKS

Abrasion resistance (0 – 4)

Cut resistance (0 – 5)

Tear resistance (0 – 4)

Puncture resistance (0 – 4)

Cut resistance (A – F)

EN 511 KÄLTE

Convective cold (0 – 4)

Contact cold (0 – 4)

Water permeability (0 – 1)

EN 407:2004

EN 407:2004

Flame resistance (0-4)

Resistance to contact heat (0-4)

Resistance to convective heat (0-4)

Resistance to radiant heat (0-4)

Resistance to small splashes of molten metal (0-4)

Resistance to large quantities of molten metal (0-4)

EN 16350:2014

Electrostatic properties of

safety gloves

DIN EN 407:2020

DIN EN 407:2020

In the latest version of DIN EN 407:2020, the first performance class is no longer named “resistance to flammability”, but is now called “limited flame spread”. If the glove has not been tested for this, a new pictogram is used. However, there are no changes to the performance classes.

Protection against mechanical risks: EN 388:2003

Protective gloves against mechanical risks bear the pictogram of the standard. The performance levels of the test must be listed in the following order:

ABRASION RESISTANCE (0 – 4)

Number of test cycles that are necessary

to wear through the test glove.

CUT RESISTANCE (0 – 5)

Number of test cycles required at constant speed

until the test glove is cut through.

TEAR RESISTANCE (0 – 4)

Force required to tear the test glove.

PUNCTURE RESISTANCE (0 – 4)

Force necessary to pierce the test glove with a standardized tip.

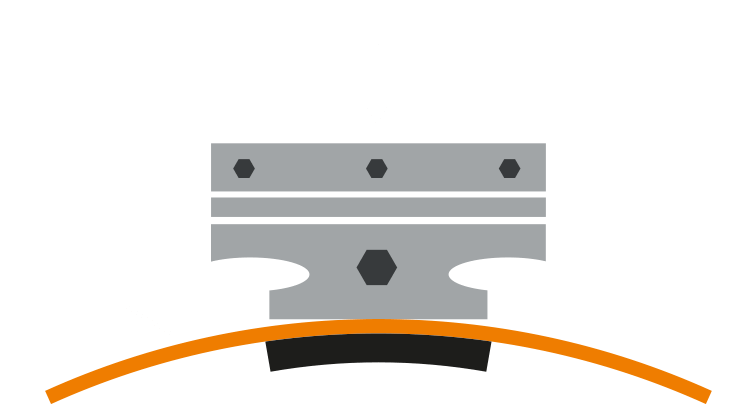

Cut resistance according to Coup-Test EN 388:2003

| 0 | 1 | 2 | 3 | 4 | 5 | |

| Abrasion resistance (cycles) | < 100 | 100 | 500 | 2000 | 8000 | – |

| Cut resistance (factor) | < 1,2 | 1,2 | 2,5 | 5 | 10 | 20 |

| Tear resistance (Newton) | < 10 | 10 | 25 | 50 | 75 | – |

| Puncture resistance (Newton) | < 20 | 20 | 60 | 100 | 150 | – |

Protection against mechanical risks: EN 388:2016

Protective gloves against mechanical risks bear the pictogram of the standard. The performance levels of the test must be listed in the following order:

Abrasion resistance (0 – 4)

Cut resistance (0 – 5)

Tear resistance (0 – 4)

Puncture resistance (0 – 4)

Cut resistance (A-F)

Determination of the minimum force with which the test specimen is cut through after 20 millimeters.

| 0 | 1 | 2 | 3 | 4 | 5 | |

| Abrasion resistance (cycles) | < 100 | 100 | 500 | 2000 | 8000 | – |

| Cut resistance (factor) | < 1,2 | 1,2 | 2,5 | 5 | 10 | 20 |

| Tear resistance (Newton) | < 10 | 10 | 25 | 50 | 75 | – |

| Puncture resistance (Newton) | < 20 | 20 | 60 | 100 | 150 | – |

| NEW | A | B | C | D | E | F |

| Cut resistance (Newton) | 2 | 5 | 10 | 15 | 22 | 30 |

Discover our new CUT LEVEL F models.

Protection against cold – Norm EN 511

Protective gloves against cold bear the pictogram of the standard. The performance levels of the test must be listed in the following order:

Climatic or industrial cold with cold transmission by convection (0 – 4)

Climatic or industrial cold in case of cold transmission by contact (0 – 4)

Water permeability (0 oder 1)

Electrostatic properties EN 16350:2014

The standard DIN EN 16350:2014 deals with electrostatic properties for protective gloves. There is no permissible labeling for ESD gloves.

Test conditions and minimum requirements of electrostatic properties of protective gloves:

- The contact resistance must be less than 100 megohms (Rv < 1,0 x 108 Ω)

- The contact resistance Rv is tested according to DIN EN 1149-2:1997

- The test atmosphere for determining the contact resistance must consist of an air temperature of 23 ± 1 °C and a relative humidity of 25 ± 5 %.

- Five samples are measured. Each individual measured value must comply with the limit value.

Protection against thermal risks (heat/fire) EN 407:2004

The standard DIN EN 407:2004 deals with the thermal risks for

protective gloves, such as contact or radiant heat, flying sparks,

fire or liquid metal.

(A) Flammability (0 – 4)

(B) Contact heat (0 – 4)

(C) Convective heat (0 – 4))

(D) Radiant heat (0 – 4)

(E) Small droplets of molten metal (0 – 4)

(F) Large quantities of liquid metal (0 – 4)

Protection against thermal risks (heat / fire) EN 407:2004

The standard DIN EN 407:2004 deals with the thermal risks for protective gloves, such as contact or radiant heat, flying sparks, fire or liquid metal.

(A) Flammability (0 – 4)

(B) Contact heat (0 – 4)

(C) Convective heat (0 – 4)

(D) Radiant heat (0 – 4)

(E) Small droplets of molten metal (0 – 4)

(F) Large quantities of liquid metal (0 – 4)

DIN – The German Institute for Standardization sets the standards. Further information on all standards and guidelines can be found on the DIN website.